To: Michelle Rozo, PhD; Senator Todd Young; NSCEB; the National Biotechnology Coordination Office (NBCO) and NIST

The U.S. is trying to scale biotechnology as national infrastructure, but we are still running mammalian biology on bespoke methods and nonstandard environments. That is the fastest way to build a “network” of facilities that cannot share workflows, cannot compare outputs, and cannot earn regulatory trust at speed. Congress is moving in the right direction by creating coordination mechanisms and directing the buildout of a defense relevant biomanufacturing network, alongside regulatory science, digital infrastructure, and biometrology tools that simplify regulation.

My proposal is straightforward: NBCO and NIST should charter a national interoperability and biometrology standards track (the science and practice of measuring biology in a way that is standardized, comparable, and traceable) for mammalian biology, a “biological operating layer” that makes methods portable across sites and makes data comparable across programs. This is how the United States avoids building 50 one off plants and instead builds a true national capability that is fast, auditable, and repeatable.

Policy has created the “brain,” but the country still lacks the “operating layer”

Multiple policy and legislative lines are converging on the same reality: biotechnology is being treated less like “health policy” and more like strategic national power, akin to semiconductors, where standards and manufacturing capacity determine who wins.

At the same time, policy is finally creating the coordination “brain”: the National Biotechnology Initiative Act of 2025 establishes a National Biotechnology Coordination Office (NBCO) in the Executive Office of the President and tasks the Initiative with national security, productivity, biological data as a strategic resource, regulatory streamlining, and workforce development.

The policy mapping is explicit about what’s still missing: an interoperable national architecture for how experiments, data, and manufacturing are actually done on the ground.

That missing layer is not abstract. It’s practical:

- If one facility’s “CHO run” is not meaningfully comparable to another facility’s “CHO run,” then tech transfer becomes reinvention.

- If one site’s cell therapy batch record does not map cleanly onto another’s, then surge capacity is fictional.

- If assay data is not generated on consistent substrates and metadata, then AI models will learn local artifacts, not biological truth.

Standards are time-to-capability not bureaucracy. Standards define interfaces, not winners; they reduce reinvention and accelerate deployment.

A “Biological Operating System”

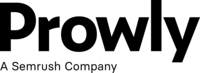

Bio-OS is a biological operating platform designed to coordinate biological environments, processes, and data across applications. It enables biology to be produced, assembled, studied, and scaled within a shared, governable framework. We are not standardizing biology, only the operating environment and metadata so biology becomes comparable.

A biological OS has three layers:

- Physical layer (the “biological chips”) human relevant, modular substrates (hydrogels, when treated as foundational materials rather than narrow tools, provide consistent and tunable environments in which biological systems can operate) for mammalian cells manufactured to the same specs everywhere so cells experience comparable environments across sites.

- Process layer (versioned “apps”) Copy and paste, version-controlled protocols that run on that physical layer, so methods are portable across labs, CDMOs, and federal facilities, rather than re-invented each time.

- Data layer (machine readable and regulator auditable) Built in sensing, standardized metadata, and traceable run histories, so every run can be compared, audited, and used for trustworthy model training.

Ronawk’s Bio-OS is a ready-to-pilot candidate implementation of this concept designed to industrialize mammalian biology by making it reproducible, portable, and measurable.

Interoperability is currently optional, and optional becomes impossible at scale

The NSCEB’s public recommendations explicitly call for NBCO in the EOP to coordinate biotechnology competition and regulation. The NBIA text builds that structure into a statutory Initiative and emphasizes biological data, regulatory streamlining, and workforce/bio-literacy.

Separately, the FY26 NDAA and related legislative action are pointing defense toward a network of commercial facilities for biomanufacturing products critical to defense, plus updates to specs, advance market commitments/offtakes, and other mechanisms that only work if outputs are comparable and trusted. S.2296 goes further: it frames infrastructure across physical capacity, economic instruments (AMCs/offtakes), regulatory science (digital infrastructure and biometrology tools), and allied demand aggregation.

All of that collapses without standards. If we do not standardize the operating layer now, we will spend the next 3-5 years funding facilities that cannot truly federate, cannot share “recipes,” and cannot generate comparable datasets for regulators or AI. In an arms race environment, that is strategic self-harm.

NIST is the right anchor: biometrology is the missing keystone

NIST’s role is precisely to make complex technical domains measurable and comparable. NIST’s bioscience and biomanufacturing work explicitly focuses on quantitative measurement tools, measurement assurance, and standards support for industry.

In biotechnology, biometrology is how we turn “trust me” into “show me”:

- What does “equivalent phenotype” mean across sites?

- What is an acceptable variance envelope for cell function, potency, or secretory activity?

- How do we validate that two manufacturing nodes are truly interchangeable?

The Bio-OS standards thesis: standardize the environment, and portability becomes real

Here is the claim I am willing to be judged on: Most of the irreproducibility, time loss, and tech transfer pain in mammalian biology is not a “data problem.” It is an “operating environment” problem. Standardize the environment and the run manifests, and you unlock:

- Faster time-to-result (because you stop requalifying the world every time you move a method).

- Higher capital efficiency (because modular suites can be replicated and repurposed).

- Faster regulatory learning (because comparability libraries become possible).

- Better AI reliability (because data is generated on consistent substrates with consistent metadata).

Bio-OS performance ranges are projections grounded in demonstrated mammalian cell work and modeled extensions (e.g., 2-3x productive yield, 30%-50% COGS reduction, 50%-70% time-to-result reduction, and 40%-60% lower effective CapEx via modular suites vs. large facilities). These ranges should be validated through pilots, not be taken on faith.

A tighter standards action plan

1. Charter a “Mammalian Interoperability & Biometrology” standards track Directive: NBCO charters; NIST hosts the technical work; agencies participate as requirements owners.

Deliverable: a national roadmap that defines interfaces, not winners.

Why this is aligned to statute: the NBIA establishes NBCO and emphasizes national strategy, biological data as a strategic resource, regulatory streamlining, and workforce development.

2. Define a Minimum Viable Biology Interface (MVBI) for mammalian workflows Think of this like “USB-C for mammalian biology.” It is not the whole device; it is the interface that makes devices interoperable. MVBI is vendor neutral; Bio-OS is one ready-to-pilot implementation.

MVBI should specify:

- Environmental specification: key physical/chemical characteristics of the culture microenvironment (human relevant substrate classes; hydration mechanics; diffusivity ranges; mechanical envelopes).

- Run manifest specification: a standard way to describe cell type, inputs, process parameters, and QC gates.

- Telemetry and metadata specification: what is minimally required for comparability (and what constitutes a regulator auditable record).

Scope control: This standards effort should be deliberately time boxed and scoped to the highest leverage layer first: mammalian cell operating environments (the controllable microenvironment and core process parameters) and assay/manufacturing telemetry (the minimum run manifest, metadata, and QA/QC signals required for comparability and auditability). The goal in Phase 1 is not to “standardize biology,” but to standardize the interfaces that make biology portable and measurable across sites. Once MVBI v1.0 is proven through pilots and reference datasets, the scope can expand in controlled increments (additional cell types, more complex modalities, broader ontology coverage) without breaking interoperability.

Standards landscape alignment: This track should be explicitly positioned as additive and harmonizing, not a reinvention of the standards ecosystem. NIST/NBCO should align the MVBI and biometrology deliverables with existing standards bodies, consortia, and regulatory science efforts leveraging what already exists, mapping gaps, and publishing interface specifications that interoperate with current practice. The objective is to create a common operating layer that can be adopted across vendors and facilities, using familiar standards mechanisms (reference materials/methods, documentary standards, test protocols) and minimizing fragmentation by coordinating rather than competing with established organizations.

3.Create NIST backed reference materials and reference methods for human relevant substrates This is where NIST adds unique value: reference materials, documentary standards, and tools that make claims testable.

Practical outputs:

- Reference materials (RMs) for key substrate property bands.

- Reference cell system methods for phenotype stability and functional output under defined conditions.

- A “comparability scorecard” for cross site equivalence.

4. Build a “comparability library” across 3-5 early sites (pilot fed standards) The cohesive themes document is explicit: the competition is about how many standardized, high-quality sites you can deploy quickly, not just who has the best single lab.

Do not start with 50 sites. Start with a tight loop:

- Stand up 3-5 reference sites (mix of federal, commercial, academic GMP/NAM nodes).

- Run matched protocols and publish the variance envelope.

- Feed results into the MVBI and reference material definitions.

5. Make standards real through procurement language (outcomes, not ingredients) Standards do not matter until they show up in solicitations. Agencies can require:

- MVBI compliant run manifests and metadata.

- Demonstrated cross site equivalence for specified outputs.

- Traceable provenance and audit trails.

This directly supports the direction toward defense relevant networks and the policy emphasis on durable guardrails, provenance, and BIOSECURE aligned supply chain constraints.

Workforce: standards are how we scale people, not just equipment

The biotech workforce is facing structural change, design/execution bifurcation, AI integration frustration, and the need for interdisciplinary fluency and continuous learning.

This is where a standardized operating layer matters:

- Training becomes portable. You can credential “Bio-OS operators” the way we credential other safety critical professions

- Execution can be distributed. Standard run manifests and validated “recipes” make remote and multi-site execution feasible without quality collapse.

- Bioliteracy becomes practical. “Bioliteracy” in the NBIA is not a slogan; it becomes a workforce standard around shared interfaces and shared records.

A Bio-OS aligned workforce model, micro credentials for GMP operators, NAM assay developers, and biomanufacturing data stewards, maps cleanly to the “workforce, standards, and bio-literacy” bottleneck identified in the policy synthesis.

“What each stakeholder gets”

- NBCO (EOP): a tangible national coordination win turning strategy into a measurable operating layer, not another committee.

- NIST: a defining leadership role in biometrology and reference materials for mammalian biology foundational to every downstream hub and COE.

- NSCEB / Congress: a credible implementation path for “hubs” that avoids stove piped infrastructure and accelerates time-to-capability.

- DoD / defense implementers: interoperable nodes that can actually surge, repurpose, and validate equivalence, aligned to the “network of commercial facilities” framing.

- Industry: reduced tech transfer friction, clearer qualification targets, and standards that lower barriers to scale (rather than bespoke compliance overhead).

12-to-36-month roadmap

0-6 months: Define interfaces, metrics, and launch the track

- Charter the NBCO/NIST Mammalian Interoperability & Biometrology Track with agency requirements owners.

- Publish MVBI v0.1 (in 90 days with minimum environment, manifest, metadata spec).

- Select 3 pilot sites (federal / commercial / academic), with clear output metrics (variance envelope, time-to-transfer, auditability).

6-18 months: Execute pilots and create reference artifacts

- Run matched protocols across sites; quantify comparability and failure modes.

- Release MVBI v1.0 and initial NIST reference methods/material classes informed by pilot results in 12 months.

- Stand up the first comparability library (the dataset that standards and later AI and regulatory science can trust).

18-36 months: Scale what works and embed standards into programs

- Require MVBI compliance in relevant solicitations and hub/COE funding instruments.

- Expand to 10-15 nodes as a reference network (defense, BARDA, NIH/FDA regulatory science partners).

- Formalize a workforce credential stack tied to MVBI-compliant operations and audit-ready records.

The immediate ask

NIST and NBCO: charter a Bio-OS aligned interoperability and biometrology standards track now.

As a concrete next step, I’m asking for a 60–90-minute scoping session with (1) NBCO designees, (2) NIST bioscience/biomanufacturing leadership, and (3) requirements owners from DoD, HHS/ASPR, NIH, and FDA to define:

- the first MVBI scope,

- the initial pilot metrics, and

- the governance structure for reference materials and reference methods.

This is not a commitment to a vendor. It is a commitment to an architecture level interface that the United States can scale faster than its adversaries.

Respectfully, Thomas W. Jantsch

President & COO, Ronawk, Inc.

President & COO, Ronawk, Inc.

On behalf of U.S. practitioners committed to a secure, resilient bio-industrial base

About Ronawk

At Ronawk, we are building a biological operating system (Bio-OS™) that acts as a compass for mammalian biology. Legacy biomanufacturing technologies were designed for microbes like yeast or bacteria. They exhaust mammalian cells, making production inefficient and cost prohibitive. Bio-OS was designed from the ground up for mammalian cells, which are the very cells needed for therapies, biologics, and regenerative medicine.

Instead of burning cells out, Ronawk’s Bio-OS cultivates them in environments that mimic the body. This yields healthier, more potent outputs at a fraction of the cost and footprint of current systems. Find us online at ronawk.com, X (Twitter), and LinkedIn.

Ronawk Media Contact

Scott Leigh

Chief Business Development Officer

+1 (913) 302-4792